Diagnostic equipment

MT Pro

Diagnostic complex

Manual

Copyright © 2009-2010 MLab. All rights reserved Version dated 06/03/2010

Content

- Introduction 4

- Scope of delivery 10

- Safety eleven

- Preparation for work thirteen

- Installing the software. thirteen

- Installing the device driver. thirteen

- Preparing a PC to work with MT Pro thirteen

- Connection 14

- Grounding schemes. sixteen

- Interface eighteen

- Window management. twenty

- Main menu 25

- Interface elements 31

- Graph Controls 32

- Moving the boundaries of the vertical axis. 33

- Changing the Scale of the Vertical Axis 35

- Offset / zero shift of the vertical axis 37

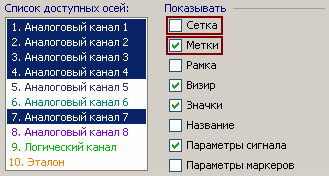

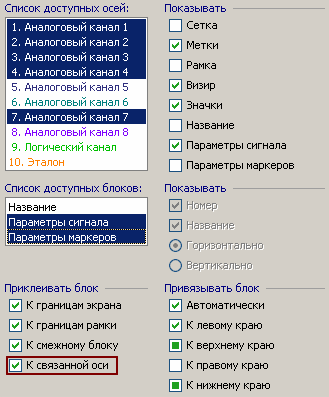

- Graphs and axes setup menu 39

- Group setting of the same type of parameters. 41

- Action groups with graphs / axes 42

- Parameter blocks 42

- Axis name block and graph 44

- Signal parameter block 45

- Block of parameters of markers 46

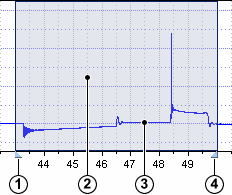

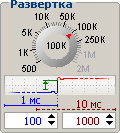

- Horizontal axis 47

- Changing the Scale of the Horizontal Axis. 47

- Navigation Along the Horizontal Axis 50

- Viewing a Signal While Recording 50

- Frame control panel 51

- Selected area 52

- Vertical and horizontal markers 53

- Pop-up menu of the home screen. 54

- Customizing Home Screen Items. 56

- Ruler 59

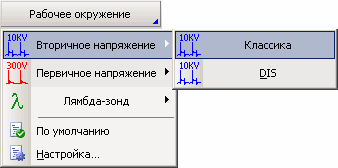

- Buttons with drop-down menu 63

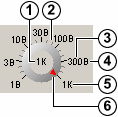

- Control knob. 64

- Graph Controls 32

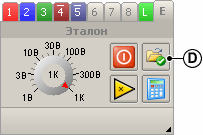

- Oscilloscope 65

Content

-

- Oscilloscope window interface 78

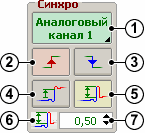

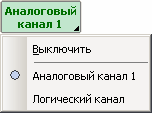

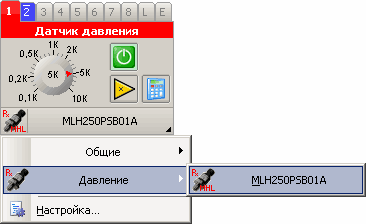

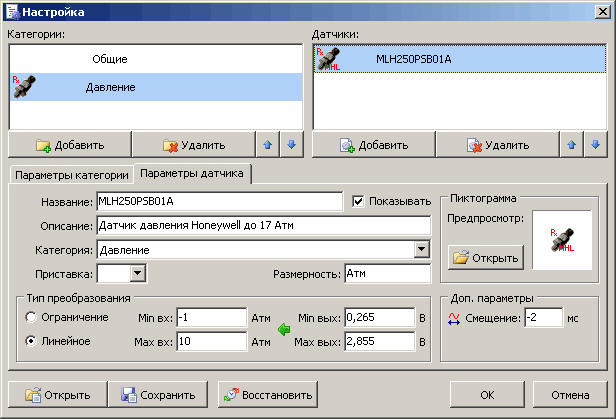

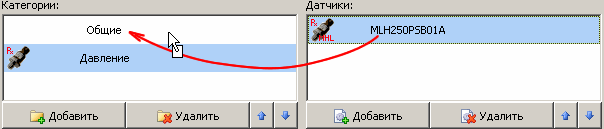

- Analog channel settings 88

- Analog channel settings list editing window 89

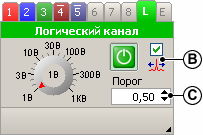

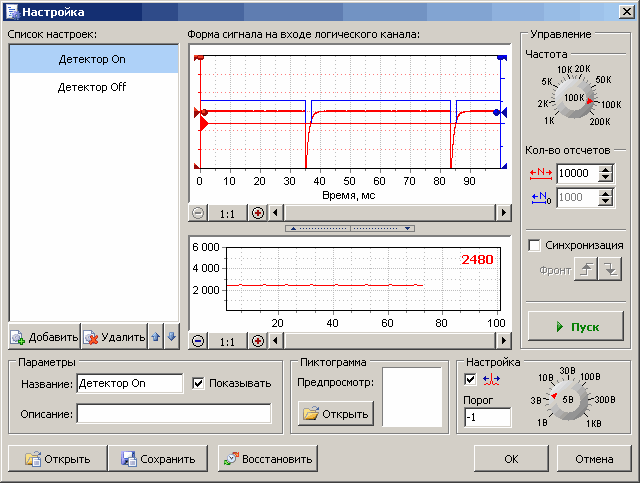

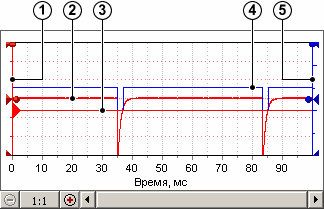

- Logical channel settings 94

- Window for editing the list of logical channels settings 96

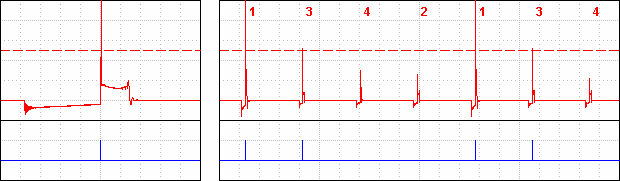

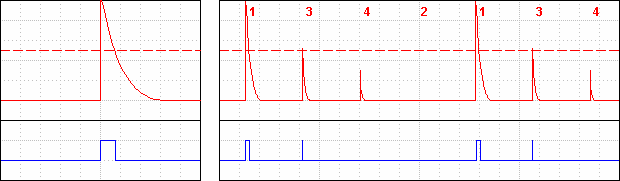

- Setting the Logic Channel as the Label of the First Cylinder 99

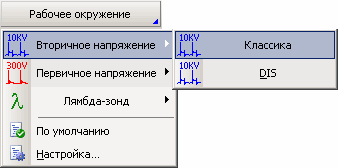

- Work environment settings 101

- The window for editing the list of settings for the working environment 102

Introduction

This Operation Manual (OM) is intended to familiarize you with the basic rules of operation of the MT Pro diagnostic complex, as well as the software (SW) supplied with the equipment. Please read the contents of this manual carefully before using the instrument.

Purpose

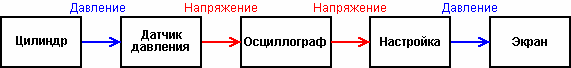

The MT Pro diagnostic complex is designed for in-place diagnostics of automotive internal combustion engines, including the ignition, fuel supply, gas distribution, power supply systems, etc., reading information from the electronic control units (ECU) of the car using the OBD II protocol (for the version of the device with built-in OBD II scanner). MT Pro is a universal measuring device that is not tied to any particular brand or model of car, i.e. allows you to diagnose all makes and models. The device almost always provides the ability to directly connect sensors and probes to the corresponding electrical circuits of the car, without the need for additional adapters, dividers, etc.

Opportunities

Opportunities

The MT Pro diagnostic complex allows you to effectively detect a malfunction in the following systems:

Ignition system

§ Determination of the condition of spark plugs and spark plug wires (carbon deposits, breaks, breakdowns)

§ Determination of operating modes and malfunctions of the ignition coil (inter-turn short circuits, control of correct connection, breakdowns)

§ Diagnostics of sensors of the ignition system (inductive, hall)

§ Determining the ignition timing (without stroboscope)

Fuel supply system

§ Electrical check of fuel injectors (turn-to-turn short circuits of the injector windings, duration of the injection phase, etc.)

§ Checking the operation of temperature sensors, throttle position, oxygen sensor, mass air flow sensor, etc.

§ Checking the operation of actuators (idle speed controller, etc.)

Gas distribution system §

Assessment of relative compression by cylinders in the starter cranking mode Compression

§ measurement in dynamics (with the engine running) and in cranking mode Determination of

§ the correct installation of the timing belt

§ Valve control

Power and Charging System

§ Checking the operation of the generator and the battery charging system

With a built-in OBD II scanner, it allows you to perform §

Vehicle identification Reading and deciphering fault codes Resetting

§ stored information about fault codes Displaying the status of sensors

§ in digital and graphical form

§

§ Display of the system status (freeze frame) at the time of the malfunction Reading and

§ interpretation of the results of the oxygen sensor test

§ Actuator control

Functionality §

Simultaneous display on the screen of data from 1,2, 3 … 7, 8 analog channels and 1 logical channel

§ Possibility of synchronization from the signals of almost all electrical circuits of the car Long signal

§ acquisition time (limited by available disk space) Possibility to save data on received signals and support

§ reports

System requirements

System requirements

Minimum

§ Operating system: Windows 98 / ME / 2000 / XP / Vista (under development)

§ Processor: Celeron / Pentium II 600 MHz

§ RAM: 64 MB (Win98 / ME) / 128 MB (Win2000 / XP) Available disk

§ space: 128 MB

§ Hard disk controller: support for DMA transfer mode Video

§ adapter: 800×600, 256 colors

§ USB interface: 1.1

Featured

§ Operating system:Windows XP SP2 § Processor:Pentium III 1 GHz or better §

RAM: 256 – 512 MB

§ Available disk space: 1 – 2 GB Hard disk controller: DMA transfer

§ mode supported Video adapter: 1024 x 768 True Color

§

§ USB interface: 2.0

Specifications

Analog channels

§ Number of universal analog channels: Number of

§ simultaneously switched on channels:

§ Channel input range:

§ Channel subranges:

§ Number of subbands of the channel: Input

§ active impedance of the channel:

eight

in oscilloscope mode: 1, 2, 4 or 8 in

recorder mode: 1, 2, 3, 4, 5, 6, 7, 8 ±1000 V

±2, ±5, ±16, ±30, ±80, ±200, ±500 and ±1000 V 8

not less than 1 MΩ

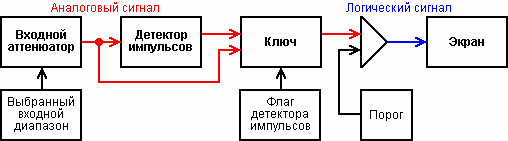

Logical channelsone)

§ Number of universal logical channels: Number of

§ simultaneously enabled channels: Channel input

§ range:

§ Channel subranges:

§ Number of subranges of the channel: DAC bit depth

§ for setting the comparison threshold: Input active

§ resistance of the channel: Optionally connected pulse

§ detector:

one

1 (visible only in recorder mode) ±1000 V

±2, ±5, ±16, ±30, ±80, ±200, ±500 and ±1000 V 8

12 bit

not less than 1 MΩ

Yes

Maximum sample rate2)

§ In oscilloscope mode: 2 MHz (in 1-channel mode) 1 MHz (in 2-channel mode) 250 kHz (in 4- channel mode) 125 kHz (in 8-channel mode)

§ In recorder mode: 500 kHz (in 1-channel mode) 250 kHz (in 2-channel mode) 166 kHz (in 3- channel mode) …

70 kHz (in 7-channel mode) 60 kHz (in 8-channel mode)

ADC bit depth3)

§ In oscilloscope mode:

§ In recorder mode:

16 bit

12 bits (lower 4 bits are ignored)

Memory depth4)

§ In oscilloscope mode:

§ In recorder mode5):

up to 262,144 samples/channel

up to 2.8 billion samples/channel

Maximum signal registration time in recorder mode6)

§ At a sampling rate of 500 kHz: At a

§ sampling rate of 500 Hz:

up to 95 minutes

up to 66 days

Galvanic isolation §

Insulation test voltage: Insulation

§ resistance: Insulation capacitance:

§

1KV for 60 seconds not less than 1000 MΩ

not higher than 60 pF

Built-in OBD II scanner § Interpreter:

§ Supported protocols:

ELM327

SAE J1850 PWM (41.6 Kbaud) SAE J1850 VPW

(10.4 Kbaud) ISO 9141-2 (5 baud init, 10.4

Kbaud) ISO 14230-4 KWP (5 baud init, 10.4 Kbaud) ISO 14230-4 KWP (fast init, 10.4 Kbaud) ) ISO 15765-4 CAN (11 bit ID, 500

Kbaud) ISO 15765-4 CAN (29 bit ID, 500

Kbaud) ISO 15765-4 CAN (11 bit ID, 250

Kbaud) ISO 15765-4 CAN (29 bit ID, 250

Kbaud) 250 kbaud)

Operating modes

§ Oscilloscope (functionally similar to a conventional analog oscilloscope)

§ Frame-by-frame (the data of each measurement (frame) are displayed in real time on the PC screen and are automatically recorded on the hard drive for further viewing / analysis) analysis)

§

Other technical specifications §

Supply voltage: from USB port 4.5 – 5.5 V

from external power supply 9 – 24 V (optional) no

§ Power consumption:

§ PC communication interface:

§ Overall dimensions of the measuring unit:

§ Weight of the measuring unit:

more than 150 mA USB 2.0 Full Speed 230 x 158 x 33 mm

Max. 1.2 kg

eight Copyright © 2009 www.mlab.org.ua

Notes:

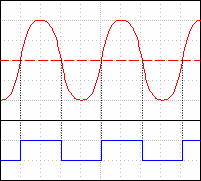

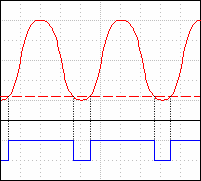

- The logical channel is functionally similar to the analog channel, except that the input signal is fed not to the ADC, but to a comparator with a comparison threshold configurable from the shell. The output of the logic channel will correspond to “1” if the value of the input voltage exceeds the set value of the comparison threshold, and “0” if it does not. This allows you to use the logical channel (without downsampling) for synchronization and labeling purposes, thereby “saving” the analog channel used for such purposes.

- The maximum sampling rate proportionally depends only on the number of enabled analog channels, the number of enabled logical channels does not affect the maximum sampling rate.

- Due to the use of 8 subranges, the overall measurement accuracy increases by 8 times.

- The memory depth decreases in proportion to the number of enabled analog channels.

- Memory depth in recorder mode is limited by available disk space and a maximum file size of 4 GB

- Subject to available disk space.

Scope of delivery

![]()

![]()

Basic delivery set No.

Basic delivery set No.

| Name | |||

| one | Measuring block | Diagnostics of electronic and

electrical systems of the car |

one |

| 2 | Interface cable USB AB | Connecting the instrument to a PC via the USB port | one |

| 3 | CD disc | Installing drivers, software and help system on a PC | one |

Safety

Safety

To avoid electric shock, injury, or exhaust fumes while using this equipment, please read the safety instructions carefully.

The manufacturer does not assume any liability for damages arising from the inability to use this device or damages (including damages arising from loss of profits, business interruption and other types of financial losses) associated with its use.

grounding

§ The room in which the equipment is operated must have a protective earth circuit, made in accordance with the “Electrical Installation Rules”. The case of a PC (except for mobile PCs powered by

§ an internal battery) must be grounded with a separate copper stranded wire with a cross-section of at least 0.5 mm2.

§ The ground terminal of the device must be grounded at the same point as the grounding of the PC with a separate copper-stranded wire with a cross-section of at least 0.5 mm2.

Connection

§ Connection of probes and sensors to the car should be carried out only with the engine turned off.

§ To avoid electric shock, probes and sensors should be initially connected to the device and only then connected to the vehicle.

§ Black crocodile clips of signal and power wires, oscilloscope probes, sensors, and adapters during measurements must be connected to the “ground” of the vehicle being diagnosed at one point.

§ Measuring and supply cords of the device must be located as far as possible from the high-voltage wires of the ignition system, exhaust manifold, and engine cooling fan.

Safety

Injury

§ Before diagnosing a car, apply the handbrake and set the gear to neutral (manual transmission) or the parking position (automatic transmission). For front-wheel drive vehicles, use brake shoes.

§ Arrange cords and cables in such a way that during diagnostics they cannot get into the rotating parts of the engine.

§ When working with a running engine, do not swap probes and sensors, and also avoid touching hot and rotating parts of the engine.

§ When diagnosing a car while driving, it is not allowed to simultaneously drive a car and carry out diagnostics. Also, while driving, you should not place the device directly in front of you, since when the airbags are triggered, the device can cause significant injury.

Accumulator battery

§ Do not place the device on the battery, as the metal case of the device can short-circuit the battery terminals, which will cause damage to both the device and the battery.

§ To prevent the possibility of an explosion of the hydrogen emitted from the battery, keep sparks away from the battery.

§ To avoid burns, keep battery acid away from hands and clothing.

Poisoning

Exhaust gases contain carbon monoxide CO and unburned fuel particles CH, as well as other toxic substances, poisoning by which can lead to serious health consequences. Make sure the work area is well ventilated. Connect the exhaust system of the car to a special ventilation system, which must be equipped with a car repair shop.

- Preparation for work

Software installation

Insert the software CD into the optical drive and run the installation file “MtPro_Setup.exe” located in the root directory of the CD. Following the instructions of the installation program, install the software to the selected directory on your PC. After installing the software, a new *.mt file type associated with the MT Pro software will be registered in the operating system, which will allow the corresponding files to be opened by double-clicking, for example, from an explorer window.

Installing the device driver

Using a USB interface cable, connect the device to one of the free USB ports on your PC. In Windows Explorer, open the directory where the software was previously installed, go to the “Driver” directory and open the ReadMe.txt file, follow the instructions to install the driver.

Preparing a PC for MT Pro

To ensure maximum performance of MT Pro when operating in the recorder mode (real-time data is recorded to the hard drive in a continuous stream), support for the DMA transfer mode must be enabled.

Enabling DMA transfer mode for Windows XP: §

Right-click on the “My Computer” icon, and then select “Properties” from the drop-down menu.

§ In the “System Properties” window that opens, select the “Hardware” tab and click on the “Device Manager” button.

§ In the “Device Manager” window, double-click “IDE ATA/ATAPI Controllers”. Right-click “IDE Primary

§ Channel”, and then select “Properties” from the drop-down menu.

§ In the Properties: Primary IDE Channel window that opens, select the Advanced Options tab.

§ In the “Device 0” and “Device 1” groups, in the “Transfer Mode:” lists, select “DMA if available”.

§ Click on the “OK” button.

§ Repeat the above steps for all available IDE channels.

§ After restarting Windows, check the set state of the transfer modes, if the DMA transfer mode is not active, then the uninterrupted operation of the device in the recorder mode at maximum frequencies is not guaranteed.

Enabling DMA transfer mode for Windows 98SE: §

Right-click on the “My Computer” icon, and then select “Properties” from the drop-down menu.

§ In the “Properties: System” window that opens, select the “Devices” tab.

§ Double click on “Disk Drives”.

§ Right-click on “GENERIC IDE DISK TYPE”, and then select “Properties” from the drop-down menu.

§ In the “Properties: GENERIC IDE DISK TYPE” window that opens, select the “Settings” tab. Check

§ the “DMA” box.

§ If the “Possible Mismatch Warning” window opens, click the “OK” button. In the “Properties: GENERIC

§ IDE DISK TYPE” window, click the “OK” button.

§ Repeat the above steps for all available “GENERIC IDE DISK TYPE”. After restarting Windows, check the

§ set state of the “DMA” flags, if the “DMA” flag is not set, then uninterrupted operation of the device in recorder mode at maximum frequencies is not guaranteed.

Connection

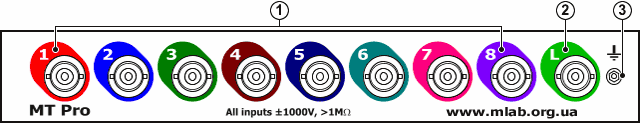

MT Pro Measuring Unit Front Panel

The front panel of the MT Pro measuring unit contains the following elements: 1. Eight high-frequency BNC connectors for universal analog channels.

- High-frequency connector type BNC universal logical channel.

- Ground terminal of the device.

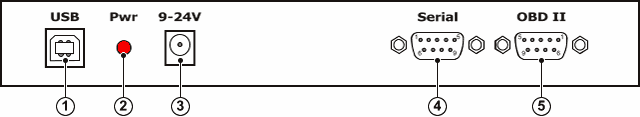

Back of the MT Pro Measuring Unit

The rear of the MT Pro Measuring Unit contains the following items:

- USB type B connector for connecting the instrument to one of the available USB ports on a PC using an AB type USB interface cable.

- Indicator of the presence of power to the device.

- Connector type DJK-02 for connecting an external DC power supply with an output stabilized voltage in the range of 9 – 24 V and an output current of at least 200 mA. It is advisable to use an external power supply if the USB port of a PC (old laptops) does not provide the necessary load capacity. As an external power source, it is possible to use standard widely used 12 V power supplies, or an external battery (the positive pole of the battery must be connected to the internal pin of the DJK connector). The battery of the vehicle being diagnosed must not be used as an external power source.

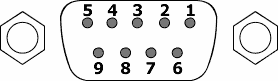

- “Serial” connector type DRB9M (male) for connecting external modules.

- Connector “OBD II” type DRB9F (female) for connecting the built-in OBD II scanner to the car’s ECU.

| Attention

To connect the instrument to a desktop PC, use only the USB ports located on the rear panel of the PC, since the internal cables of the front panel USB ports are usually not shielded. |

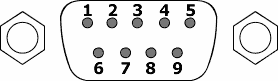

Connector pins “Serial”:

- GND – device case.

- RxD – data receiving line via RS-232 interface.

- ТxD – data transmission line via RS-232 interface.

4. +5 – output of the internal battery voltage converter to 5 Volts.

- GND – device body.

- GND – device case.

- A – non-inverting exchange line via RS-485 interface.

- B – inverting exchange line via RS-485 interface.

- Vbat – contact for connection to the positive pole of the battery.

Connector pins “OBD II”:

- GND – device case.

- ALDL (under development).

- CAN-H.

- ISO-K / K-Line.

- CAN-L.

6. J1850 Bus-.

7. J1850 Bus+.

- ISO-L / L-Line.

- Vbat – contact for connection to the positive pole of the battery.

Grounding schemes

The grounding of the instrument and the PC to which the instrument is connected must be carried out in accordance with safety regulations.

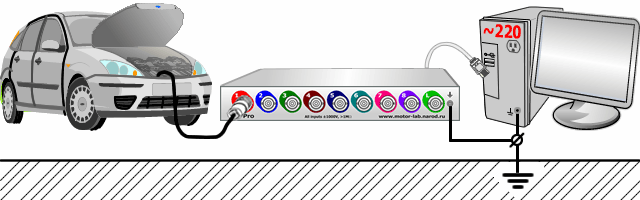

Grounding diagram of the instrument and stationary PC

The PC case and the ground terminal of the device are grounded at one point with separate copper stranded wires with a cross section of at least 0.5 mm2.

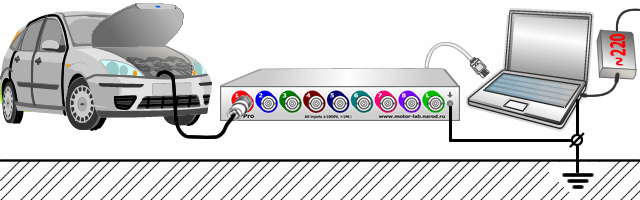

Grounding diagram of the device and mobile PC powered by a network adapter The PC case and the ground terminal of the device are grounded at one point with separate copper stranded wires with a cross section of at least 0.5 mm2.

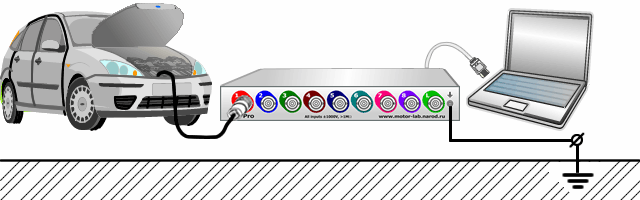

Grounding diagram of the device and a mobile PC powered only by an internal battery The ground terminal of the device is grounded by a separate stranded copper wire with a cross section of at least 0.5 mm2.

Interface

5. Interface

The MT Pro software has a fairly simple and easy-to-use interface based on the concept of user-configurable windows integrated into the application.

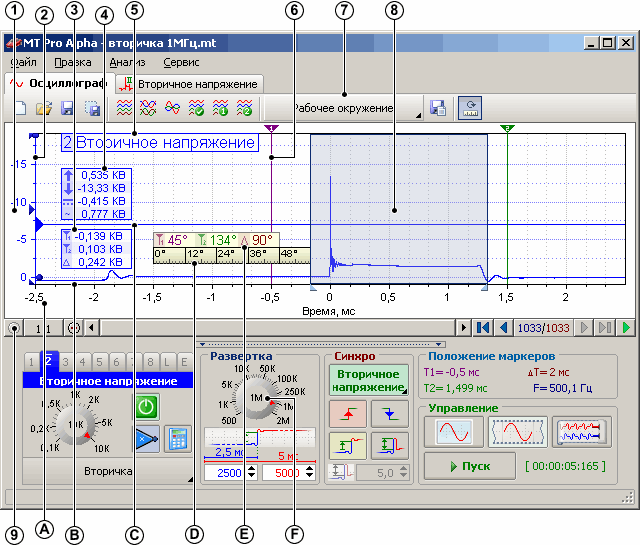

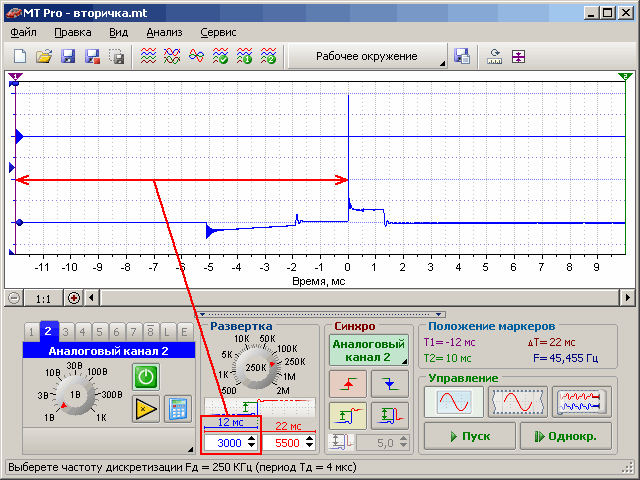

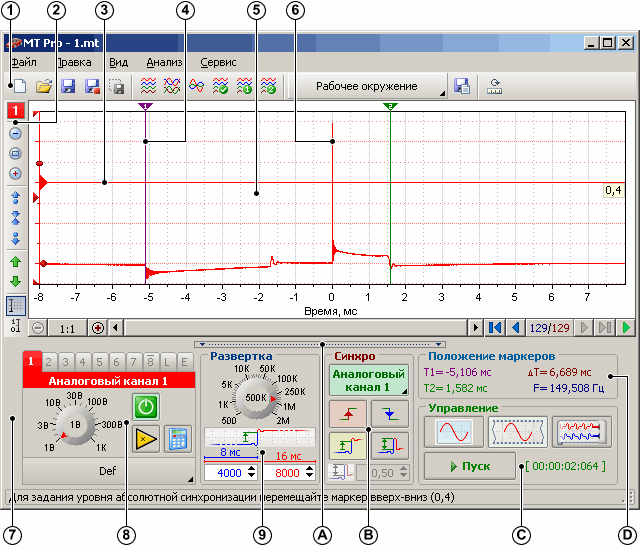

Main program window

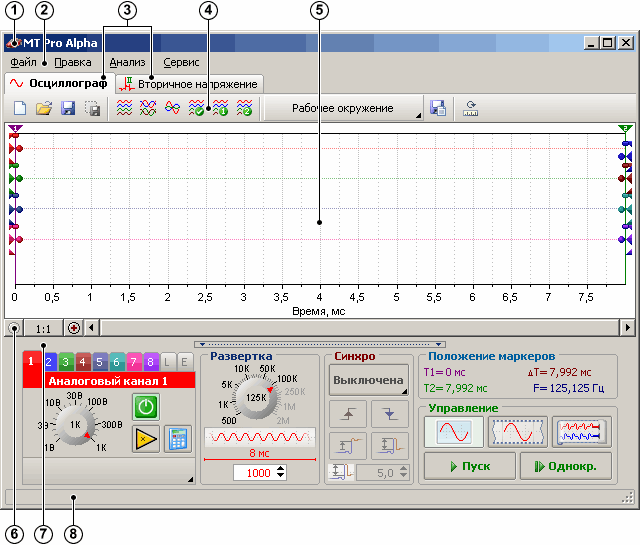

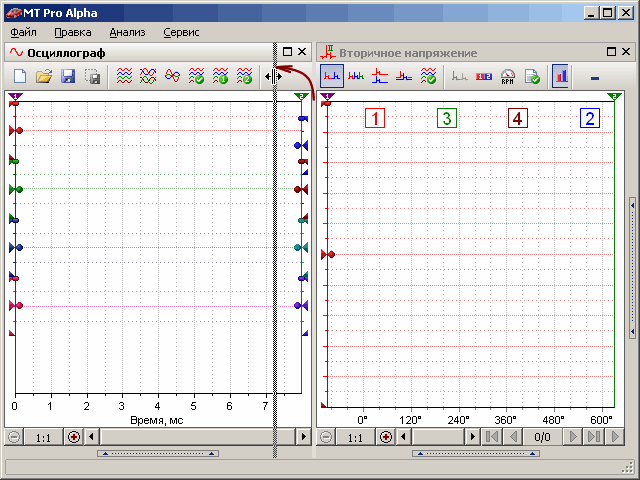

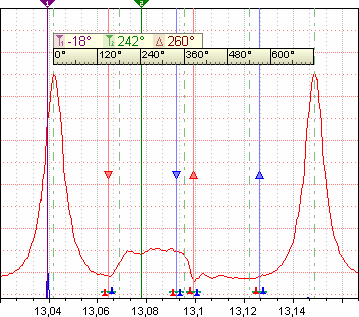

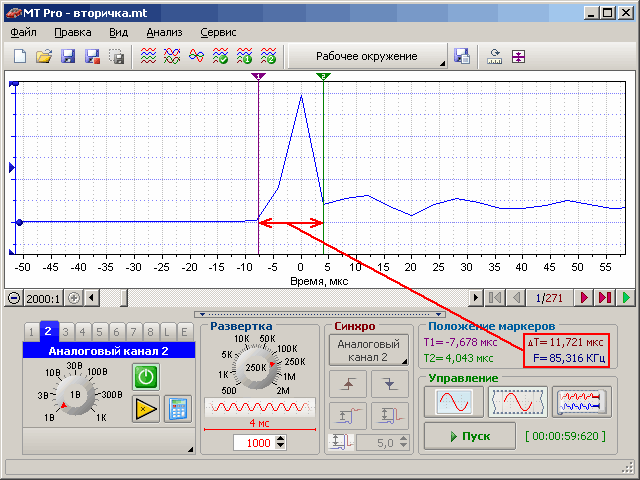

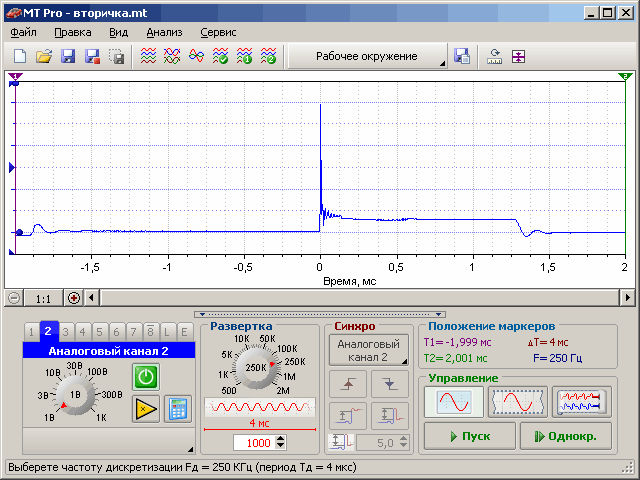

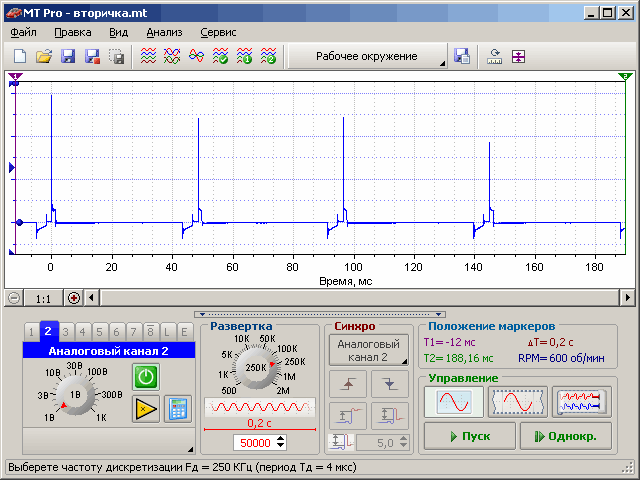

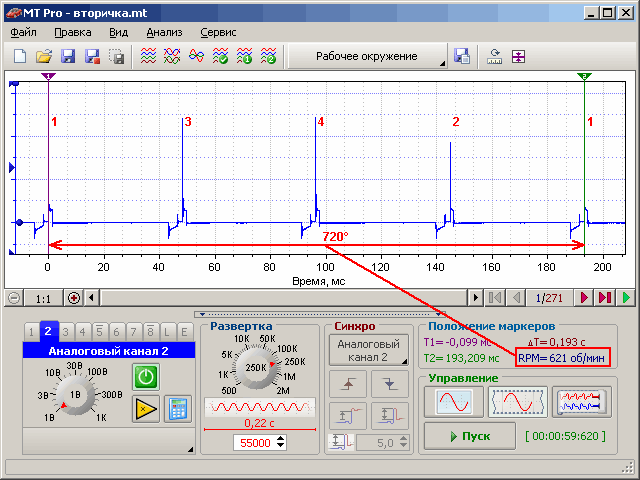

After downloading the MT Pro application, the main program window will appear on the PC screen, the appearance of which with the “Secondary voltage” window open is shown in the figure below.

The main program window consists of the following functional parts:

- The standard title of the Windows application window, which displays the name of the program and the name of the current data file.

- Main menu with pop-up submenus, which always occupies the top of the main window and is always visible regardless of the currently selected additional window.

- Titles of open windows integrated into the application.

- Toolbar with pictogram buttons, partially duplicating some menu commands.

Interface

- The working screen, which displays the graphs of the recorded signals of all active channels, as well as the controls for the graphs and displayed channel parameters.

- Scroll bar and horizontal axis scale controls.

- Control panel, which contains the main controls for the parameters of the current window.

- Status bar, which displays the current state of the device, as well as a brief hint about the interface element over which the mouse pointer is located.

| Advice

In order to quickly get brief information about any element of the program interface, simply move the mouse pointer to it and read brief information about it in the status bar. |

Copyright © 2009 www.mlab.org.ua nineteen

6. Window management

The windows integrated into the application can be organized as tabs, floating windows or docked panels at the user’s request. The last window arrangement is automatically saved and restored the next time you start the program.

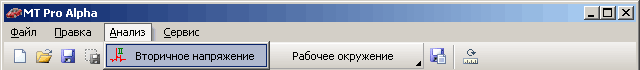

Opening windows

To open one of the windows integrated into the application, select the appropriate menu item from the “Analysis” pop-up submenu. For example, to open the window for analyzing the ignition system based on the secondary voltage, you must select the menu item “Analysis” > “Secondary voltage”.

After that, the title of the opened window “Secondary voltage” will appear.

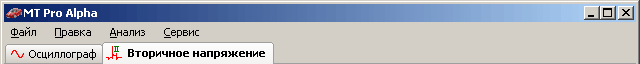

| Note

The “Oscilloscope” window title is automatically hidden when only one oscilloscope window is open (to save screen space). |

| Advice

The fewer additional windows you open, the less system resources the program will need, and the faster the program will load the next time you start it. |

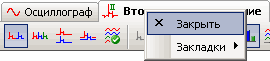

Closing windows

To close the additional window, just do one of the following: §

Re-select the menu item from the pop-up submenu “Analysis” corresponding to the window being closed.

§ Right-click on the title bar of the window and select “Close” from the pop-up menu.

![]()

§ Click on the “Close” button if the window is in the state of a docked panel or a separate floating window

| Note

The Oscilloscope window cannot be closed. |

twenty Copyright © 2009 www.mlab.org.ua

Window states

Windows integrated into applications can be in the following three states: § As tabs

§ In the form of fixed panels, the location and size of which can be easily adjusted

§ As a separate floating window

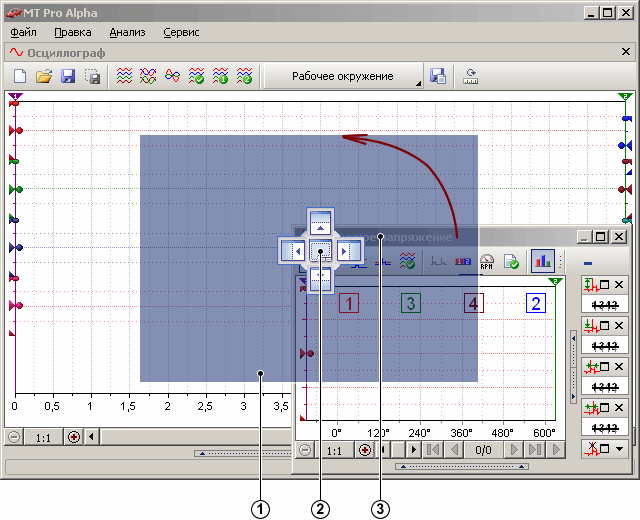

Moving windows

Moving windows is done by dragging the window by its title bar. To start moving a window, left-click on the title bar of the corresponding window, and then, without releasing the left mouse button, drag the window to the specified position. Simultaneously with the beginning of the dragging of the window, several semi- transparent markers in the form of arrows will appear on the screen, indicating the location of the docking of the window in the new location, which is indicated by the semi-transparent window outline. To fix the location of a window on one of the sides of another window, move the mouse pointer to the marker with the corresponding arrow, a window outline will appear in the specified location. To dock a window as a tab, move the mouse pointer to the center marker, or drag the window title to the title of another window.

- New window location (window outline)

- Markers indicating the place of fixing the window

- Title of the floating window

| Advice

To prevent the window from docking while moving it, hold down thectrl. |

Window management

To resize windows in the form of docked panels, move the mouse pointer to the separator of two or more windows, when the mouse pointer becomes a separation line, left-click on the separator area and drag it to the desired position.

| Advice

To set the maximum possible size of the window, just click on the “Maximize” button. |

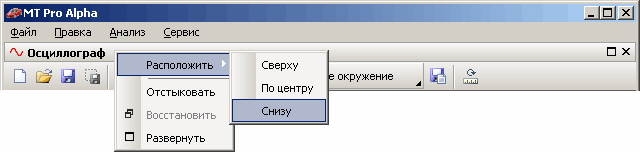

To quickly set one of the predefined window locations as a docked pane, it is possible to use the window title pop-up menu, which is invoked by right-clicking on the window’s title bar.

To undock a window (transfer to the state of a separate floating window), just double-click on the title of the corresponding docked window, or use the pop-up menu of the window title.

To cycle through open additional windows, use the keyboard shortcutCtrl+Tab, and for looping in reverse order, the keyboard shortcutCtrl+Shift+Tab.

| Advice

If you need to restore the default location of all windows, close the application, then delete the Desktop.cfg file located in the same directory as the application executable file. |

Main menu

![]()

![]()

![]()

![]()

![]() File menu– file operations

File menu– file operations

| New (Ctrl+N) | ||

| Open (Ctrl+O) | Open a file with signal data and parameters of the registration process. File format (*.dat) of the previous version of the oscilloscope is supported | |

| Save (ctrl+s) | Save signal data and parameters of the registration process in a file, or export signal data to one of the publicly available file formats | |

| Save fast (Alt+S) | Save signal data and registration process parameters in a file named “MT Pro yy.mm.hh hh-mm-ss.mt” in the Data folder. | |

| Save dedicated area (Shift+Ctrl+S) | Save data about the selected section of the signal in a file or export the data of the selected section to one of the publicly available file formats |

![]()

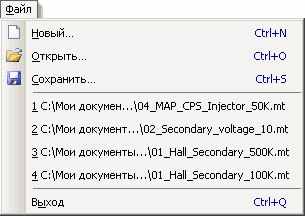

![]() List of recently used files

List of recently used files

Exit (ctrl+q)

Terminate the application

To provide quick access to the last used files (open or saved), the program automatically generates the corresponding list in the “File” menu from the last 9 used files.

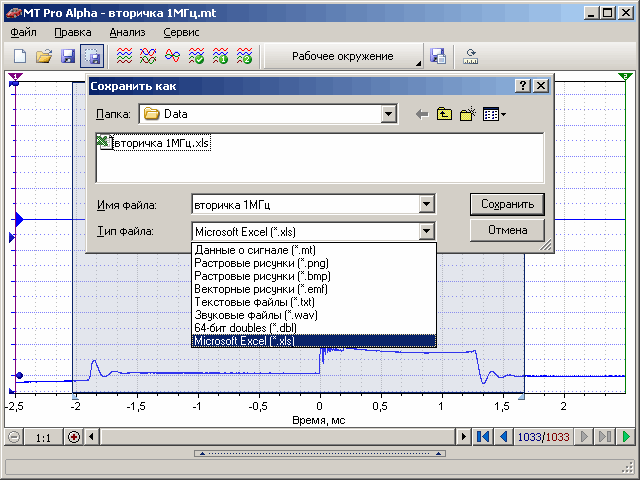

Data export

The software allows you to save signal data (export) in several commonly available file formats. It is possible to export both all signal data and a selected / visible section of the signal data. To export, when saving data, in the “Save as” dialog box, in the “File type” list, you must select one of the supported file export formats.

Signal data (*.mt)

Signal data, registration process parameters, channel parameters, control parameters, ruler parameters, etc. are packed into a single file of the native format of the MT Pro program.

Raster drawings (*.png)

The data is saved as a Web-optimized bitmap that can be opened with virtually any graphics viewer or hosted on the Internet.

Raster pictures (*.bmp)

The data is saved as a regular bitmap image that can be opened with Microsoft Paint, imported into Microsoft Word, or compressed into a more compact format (JPEG, GIF, or PNG).

Vector drawings (*.emf)

The data is saved as a vector drawing, which can be opened by Microsoft Paint, imported into Microsoft Word. Mainly intended for reporting.

Text files (*.txt)

The data is saved as a text block containing channel names and data columns separated by tabs. The file can be opened with Notepad or Microsoft Word.

Sound files (*.wav)

The data is saved as an MS Windows Wave PCM audio file, which can be opened in any program for editing or listening to audio files.

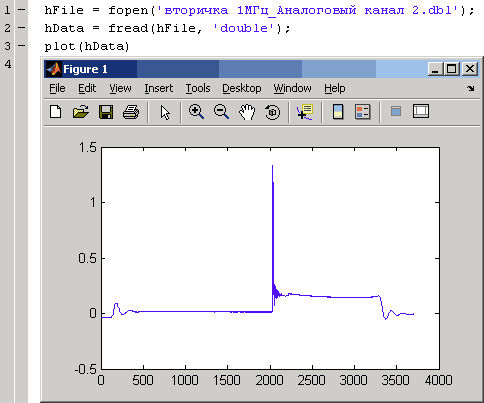

64-bit doubles (*.dbl)

The data is stored as arrays (contiguous block of double precision floating point numbers). Moreover, the data of each channel and time axis are stored in a separate file (the first half of the file name matches the specified file name, and the second half is determined by the name of the corresponding channel). The file can be imported into many programs that support reading arrays of double precision numbers (Matlab, Cool Edit Pro), and also used to import data into software developed by users. For example, to import data into Matlab, you need to execute the following code:

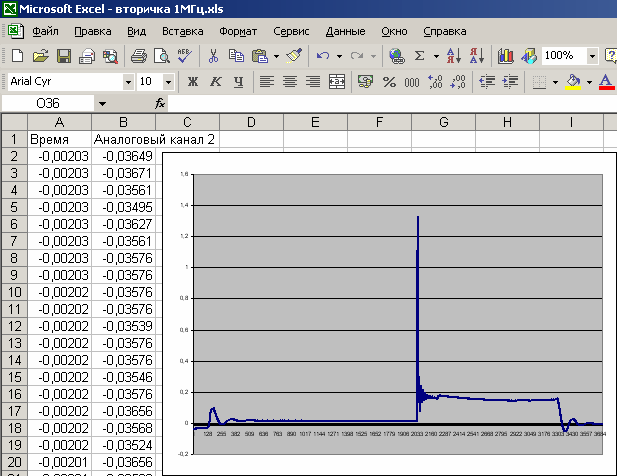

Microsoft Excel (*.xls)

The data is saved in a format compatible with the Microsoft Excel format. The file can be directly opened in Microsoft Excel for further analysis or plotting.

Edit menu – operations with a selected section of the signal

![]()

![]()

![]()

![]()

Copy as bitmap (

Shift+Ctrl+C)

Copy the selected section of the signal to the clipboard as a

bitmap

Copy as vector drawing (

Shift+Ctrl+X)

Copy the selected section of the signal to the clipboard as a

vector drawing

Copy as text block (Shift+Ctrl+T)

Copy the selected section of the signal to the clipboard as a text

block

Save a snapshot of the active

window (Ctrl+PrintScreen)

Automatically save a screenshot of the active window as a PNG file named “MT Pro yy.mm.hh hh-mm-ss.png” to the Screen

folder created automatically when the first screenshot is saved

![]()

![]()

![]() View menu – show/hide controls

View menu – show/hide controls

Analysis menu – operations with windows diagnostics of automotive systems

![]()

secondary voltage

Show/Hide Ignition System Analysis Window Based on

Secondary Voltage

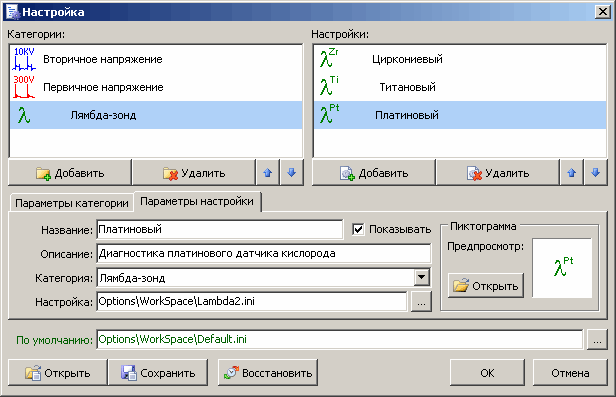

Menu “Service”– operations with application settings

![]()

![]()

![]()

![]()

![]()

Download working environment

Open the settings file and load typical application settings

(registration process parameters, channels, axes…)

Load view settings

Open settings file and load basic view settings (colors of controls,

parameters of axes, blocks…)

Load axle positions

Open settings file and load positions of all axes

Save settings

Save all current application settings to a file

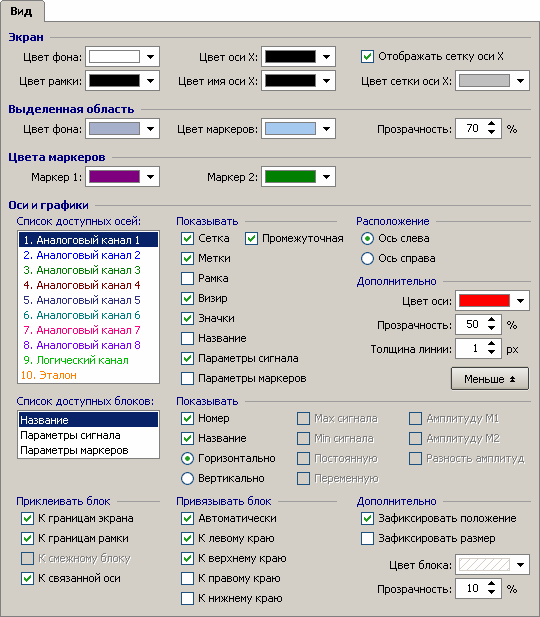

Setting

Open application settings window

The main difference between the menu items for loading settings is the composition of the settings that are taken into account (loaded and installed). The use of several options for considering settings allows you to download and install settings that are necessary only at a given moment in time, for example, download and install only the screen positions of all axes without changing the parameters of the registration process, channel settings, etc.

While loading working environmentthe following settings are taken into account: §

Global oscilloscope window settings specified in the application settings dialog.

§ Settings for all channels and parameters of the registration process.

§ The main parameters of the axes (offset and zero shift, scale, screen positions and placement of the axis).

§ Additional parameters of axes and blocks (visibility of the grid, labels, blocks, block bindings, etc.).

§ Auxiliary parameters of axes and blocks (line thickness, color of the axis, graphics, blocks, etc.). Line

§ options.

| Advice

Loading the working environment is advisable to use for quick reconfiguration of almost all parameters of the oscilloscope window, for example, when switching from one typical measurement to another. |

While loading view settings the following settings are taken into account: §

Colors of the screen, selected area, markers, axes, graphs and corresponding blocks Additional

§ parameters of axes and blocks (visibility of the grid, labels, blocks, block bindings, etc.).

§ Auxiliary parameters of axes and blocks (line thickness, color of the axis, graphics, blocks, etc.).

| Advice

Loading view settings actually takes into account all settings from the “View” tab of the settings dialog, i.e. is equivalent to a skin and is intended only for designing the application interface. |

While loading axle positionsonly take into account: §

Axis position on screen Axis

§ placement (left or right)

thirty Copyright © 2009 www.mlab.org.ua

Interface elements

For effective interaction and management of MT Pro, based on the specifics of auto-diagnostic applications, a number of specialized interface elements have been developed, understanding the capabilities of which is the key to the most efficient and convenient operation of the complex as a whole. The time spent on studying the capabilities of the developed interface elements will return with a torus in the process of self-diagnosis.

Interface elements take into account the following number of factors required for car diagnostics:

§ Efficient management of multiple graphs displayed simultaneously on the screen. Possibility of

§ both individual and group settings of almost all parameters. Almost complete duplication of

§ control using the keyboard.

§ Support for generic settings with one click.

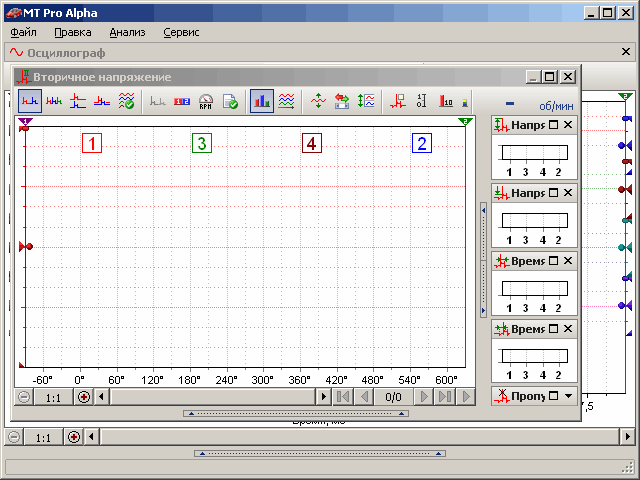

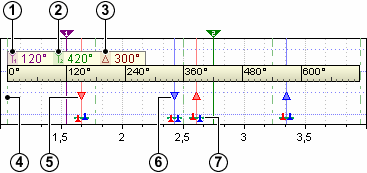

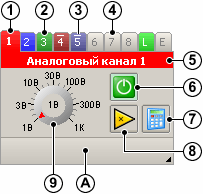

The figure shows the following interface elements:

- The area of the scale of the vertical axis, which serves to display labels and quantify the values of the corresponding graph.

- The vertical axis and the corresponding elements for controlling the position of the axis on the working screen and setting the chart scale.

- A block of information about the signal parameters under the markers.

- Block of information about the general parameters of the signal.

- Block with serial number and name of the graph.

- Vertical marker for detailed viewing of signal parameters.

- Button with a drop-down menu to select one of the preset settings.

- Selected area inside, which is the selected section of the signal.

- Scroll bar with horizontal axis scale and frame controls.

- An area of the horizontal axis scale that displays the horizontal axis labels and is also used to scroll the horizontal axis with the mouse.

- The frame of the working screen inside which all axes and graphs are displayed.

- Horizontal sync level marker.

- Ruler (floating axis with markings in degrees).

- Ruler block that displays the position of markers in ruler coordinates.

- Control knob (knob) for quick selection of single and predefined values.

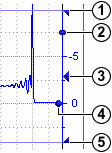

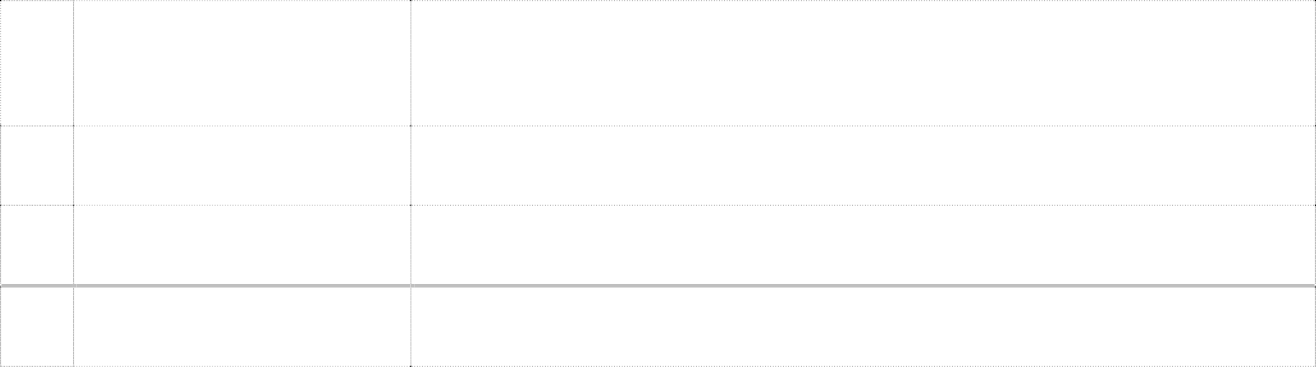

Graph Controls

Graphs are intended for visual display of recorded or analyzed signals. Each chart is inherently linked to its respective vertical axis, which is effectively controlled by the following elements:

-

-

Marker for moving the upper boundary of the axis (setting the screen height of the axis)

Marker for moving the upper boundary of the axis (setting the screen height of the axis)- Slider for adjusting the scale of the axis (program sensitivity of the channel)

- Marker for moving the axis along the vertical borders of the screen frame

- Slider Offset / Zero Shift (Zero Amplitude Value)

- Marker for moving the lower border of the axis (setting the screen height of the axis)

-

One of the charts is always active and the corresponding chart/axis control shortcuts only apply to the active chart/axis. The graph automatically becomes active after clicking on one of the markers or sliders, or after clicking within the scale area of the corresponding vertical axis.

![]()

![]() Keyboard shortcuts used to manipulate charts/axes, usually contain a modifier altor keys , . Keyboard shortcuts for performing a group of actions with graphs / axes, for example, aligning all axes, or group setting the same type of parameters, usually also contain a modifierctrl.

Keyboard shortcuts used to manipulate charts/axes, usually contain a modifier altor keys , . Keyboard shortcuts for performing a group of actions with graphs / axes, for example, aligning all axes, or group setting the same type of parameters, usually also contain a modifierctrl.

When you hover the mouse pointer over one of the markers / sliders, the pointer will take the form corresponding to this marker / slider, and the status bar will display brief information about the possibilities of using the current marker / slider. When moving one of the markers / sliders, the status bar will display information about the current value of the parameter being changed corresponding to the current marker / slider.

When you hover the mouse pointer over one of the markers / sliders, the pointer will take the form corresponding to this marker / slider, and the status bar will display brief information about the possibilities of using the current marker / slider. When moving one of the markers / sliders, the status bar will display information about the current value of the parameter being changed corresponding to the current marker / slider.

| Advice

To get a brief information about the capabilities and purpose of the markers / sliders, just move the mouse pointer to the marker / slider and read the brief information about it in the status bar. |

Moving the boundaries of the vertical axis

Boundary move markers axes (1) and (5) are designed to set the screen height of the axis and thereby change the area occupied by the corresponding graph on the screen. These markers allow you to reduce the height of the axis, for example, for less informative signals (logical signals), or vice versa, to increase the height of the axis for more informative signals (analog signal of complex shape), which require a more detailed visual analysis.

When you hover the mouse pointer over the marker for moving the upper / lower boundaries of the axis, the mouse pointer will take the following form:

To move one of the axis boundaries, you need to move the mouse pointer to the corresponding marker, after the mouse pointer takes the above form, left-click on the marker and drag it to the desired position, the corresponding axis boundary will move after the marker. While changing the screen height of an axis, its current value as a percentage of the height of the work screen frame will be displayed in the status bar. Release the left mouse button to stop moving the axis border and fix the set screen height of the axis.

![]()

![]()

– moving the upper border of the axis

– moving the lower border of the axis

Keyboard Shortcuts:

![]()

![]()

![]()

![]() Move axis top up/down: Shift+ , Shift+ Move axis bottom up/ down: Ctrl+ , Ctrl+

Move axis top up/down: Shift+ , Shift+ Move axis bottom up/ down: Ctrl+ , Ctrl+

Axis move marker (3) is designed to move the axis along the vertical borders of the screen frame (set the vertical position of the axis), and is also used when expanding, collapsing and stretching the axis. This marker allows you to arrange all displayed graphs in the most convenient vertical order.

When you hover the mouse pointer over the axis move handle, the mouse pointer will look like this:

![]()

![]()

To move the axis, move the mouse pointer to the axis move marker, after the mouse pointer takes the above form, left-click on the marker and drag it to the desired position, the axis center will move after the marker. While moving the axis, the value of the current position of its center as a percentage of the height of the frame of the working screen will be displayed in the status bar. To stop moving the axis and fix the set position of the axis, release the left mouse button.

Keyboard Shortcuts:

![]() Move axis up:

Move axis up:

![]() Move axis down:

Move axis down:

Foraxis reaming to full screen, move the mouse pointer to the marker for moving the axis, press the key Shift, after the mouse pointer takes the form of expanding the axis, left-click on the marker for moving the axis without releasing the key Shift.

To restore the previous size of the axis (before expanding), you must repeat the same steps as when expanding the axis, i.e. click, on the handle of moving the axis while holding down the keyShift.

– expanding the axis to full screen

Expanding the axis is convenient to use to quickly analyze the details of the graph, and after the analysis is completed, it is also possible to quickly restore the previous dimensions of the axis, while the dimensions of the remaining axes do not change.

Foraxis folding to the minimum allowable screen height, you must move the mouse pointer to the marker for moving the axis, press the key ctrl, after the mouse pointer takes the form of the axis collapse, left-click on the axis movement marker without releasing the key ctrl.

To restore the previous size of the axis (before collapsing), you must repeat the same steps as when collapsing the axis, i.e. click, on the handle of moving the axis while holding down the key ctrl.

– collapsing the axis to the minimum allowable screen height

Axis collapse is convenient to use for quick temporary release of the screen space occupied by the current chart, and a more detailed visual analysis of other charts, after which it is possible to restore the previous axis sizes just as quickly, while the sizes of the other axes do not change.

| Note

When expanding and collapsing the axes, it is possible to restore their previous sizes only if no additional actions were performed on the corresponding axes in the expanded / collapsed state related to their movement or resizing. |

Foraxis stretchto the maximum allowable screen height, and at the same time shrinking other axes visible on the screen to the minimum allowable screen height, you must move the mouse pointer to the axis move marker, after the mouse pointer changes to move the axis, double-click on the axis move handle. Axis stretching is convenient to use when it is necessary to conduct a detailed visual analysis of the current chart, without the need to analyze other charts visible on the screen.

Foraxis stretchto the maximum allowable screen height, and at the same time shrinking other axes visible on the screen to the minimum allowable screen height, you must move the mouse pointer to the axis move marker, after the mouse pointer changes to move the axis, double-click on the axis move handle. Axis stretching is convenient to use when it is necessary to conduct a detailed visual analysis of the current chart, without the need to analyze other charts visible on the screen.

Keyboard shortcut:

Stretch axis:Alt+PgUp

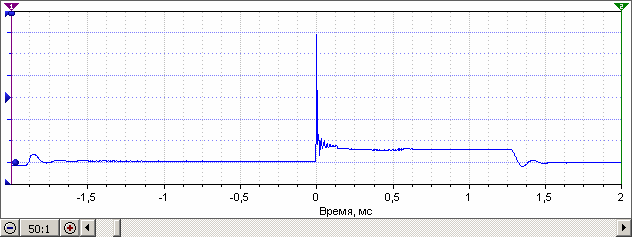

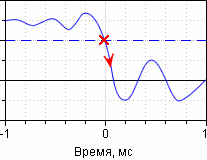

Change the scale of the vertical axis

Axis scale adjustment slider(2) is designed to smoothly increase the vertical scale of the graph (the amplitude value between adjacent scale marks), and thereby greater detailing of signal sections with small amplitudes against the background of signal sections with relatively large amplitudes. The slider provides a smooth change of scale within the range from 100% to 1000% to the initially set span of the vertical axis, which, for example, for an oscilloscope is set using the channel input range selection knob.

To change the scale of the vertical axis, move the mouse pointer to the slider for adjusting the scale of the axis, after the mouse pointer takes the form of adjusting the scale of the axis, left-click on the slider and drag it to the desired position, while the scale of the axis will change in accordance with the movement of the slider – the closer the slider is to the center of the axis, the greater the magnification, and vice versa. While changing the axis scale, its current value as a percentage will be displayed in the status bar. To end the scaling and fix the set scale of the axis, release the left mouse button.

![]()

– axis scale adjustment

Keyboard Shortcuts:

Zoom in 1.5 times:Alt+’+’ Zoom out 1.5 times:Alt+’-‘ Set initial scale (100%) :Alt+’/’

Zoom in 1.5 times:Alt+’+’ Zoom out 1.5 times:Alt+’-‘ Set initial scale (100%) :Alt+’/’

| Advice

To simultaneously change the scale of all visible vertical axes, press the key before moving the sliderctrl, after which, in accordance with the movement of the slider, the scale of all visible vertical axes will change simultaneously. |

The scaling methods described above perform scaling only relative to the current zero value of the axis (software zero), which is not very convenient if it is necessary to detail signal sections with small amplitudes in the presence of a large constant component, for example, detailing small fluctuations within the combustion area against the background of a large direct combustion voltage .

For scaling without reference to the current zero value of the axis, scaling is provided relative to the current position of the mouse pointer within the boundaries of the axis, which is temporarily taken as the “center” of scaling.

Forchanging the scale of the vertical axis with the mouseit is necessary to move the mouse pointer to the scale area of the corresponding vertical axis and press the keyalt, after the mouse pointer takes the form of a magnifying glass (a reticle indicating the “center” of zooming can also be displayed), click the left mouse button to zoom in, the right mouse button to zoom out, the middle mouse button to set the initial zoom. With each click, the scale will change by 1.5 times, except in the case of setting the initial scale, which will be set after the first click.

![]()

– scaling start (‘+’ – increase with the left button, ‘-‘ – decrease with the right button)

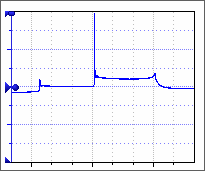

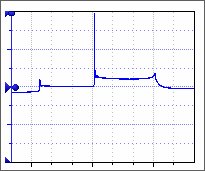

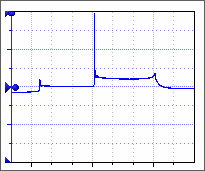

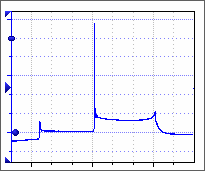

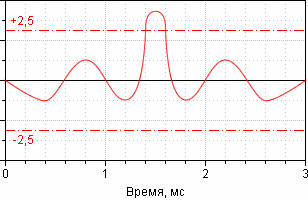

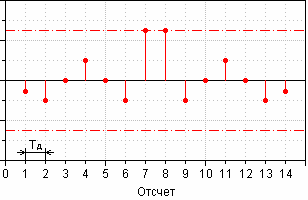

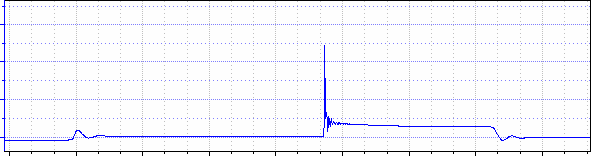

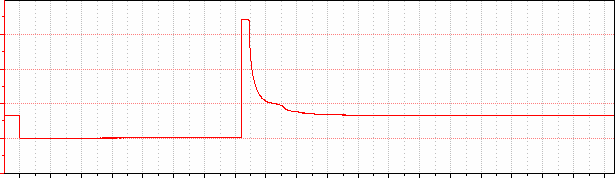

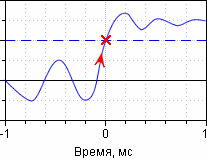

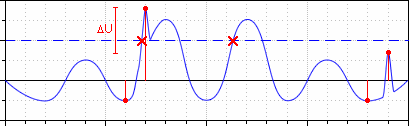

An example of changing the scale of the vertical axis with the mouse:

Initial scale 100%

Zoom slider 760%

Mouse zoom 760%

As you can see, when zooming with the slider, the oscillations under consideration within the combustion area are partially outside the screen, while at the same time, when zoomed in with the mouse, the oscillations in question are located in the center of the axis – in the most convenient place for their further visual analysis.

The only drawback of the method used in the example considered is that in order to zoom in to 760%, it was necessary to click 5 times with the left mouse button. To reduce the number of clicks and preserve the possibility of scaling without being tied to the current zero value of the axis, scaling is provided using the scaling box.

Forscaling with frameit is necessary to move the mouse pointer to the scale area of the corresponding vertical axis and press the keyalt, after the mouse pointer takes the form of a magnifying glass, click the left mouse button to zoom in or the right mouse button to zoom out, and then, without releasing the mouse button, select the required signal section using the semi-transparent frame that appears. To complete the zoom, release the mouse button, and to interrupt the zoom, press the key Escuntil the mouse button is released. When zooming in, the selected area will be enlarged by the entire screen height of the axis, when decreasing, the selected area sets the required screen height of the axis.

![]() When zooming with a frame, the mouse pointer changes to the following:

When zooming with a frame, the mouse pointer changes to the following:

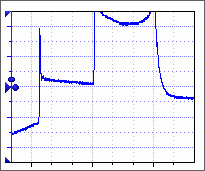

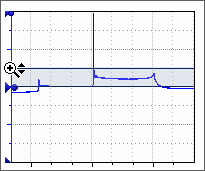

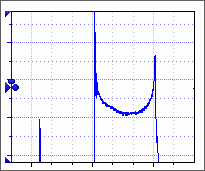

An example of changing the scale of the vertical axis using the zoom box:

Initial scale 100%

Dedicated area

Scale result

As can be seen when zoomed in using the zoom box, the vibrations under consideration are located in the center of the axis – in the most convenient place for their further visual analysis.

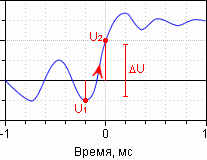

Shift/zero shift of the vertical axis

Offset / zero offset slider (4) is designed to change the zero value of the axis (software zero) within the boundaries of the axis when zero is shifted, and without being limited by the boundaries of the axis when shifting zero. Zero offset is useful when analyzing unbalanced signals relative to the base level. Zero shift is convenient to use when it is necessary to perform a detailed visual analysis of signal sections with small amplitudes in the presence of a large constant component.

For zero offset you need to move the mouse pointer to the zero offset slider, after as the mouse pointer takes the form of a zero offset, left-click on the slider and drag it to the desired position, while the zero value of the axis will move after the slider. During a zero offset, its current relative value as a percentage of the span of the axis will be displayed on the status bar. To end the zero shift and fix the set value, release the left mouse button.

For zero shiftyou need to move the mouse pointer to the zero offset slider, press the key Shift, after the mouse pointer takes the form of a zero shift, left-click on the slider and drag it to the required position, while the zero value of the axis will move after the slider. During a zero shift, its current absolute value will be displayed on the status bar. To end the zero shift and fix the set value, release the left mouse button.

Advice

To simultaneously shift / shift zero of all visible vertical axes, press the key before moving the slider ctrl, after which the zero value of all visible vertical axes will move in accordance with the movement of the offset / zero offset slider.

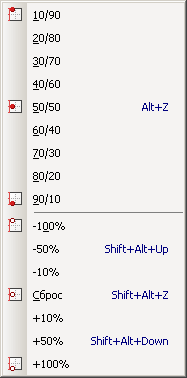

To set one of the predefined zero offset values or zero offset to one of the specified values relative to the axis span, it is possible to use the corresponding offset / zero offset setting pop-up menu, which is called by right-clicking on the zero offset slider.

Keyboard Shortcuts:

Keyboard Shortcuts:

![]()

![]() Shift zero up by 10%: Alt+ Shift zero down by 10%: Alt+ Reset zero offset: Alt+Z

Shift zero up by 10%: Alt+ Shift zero down by 10%: Alt+ Reset zero offset: Alt+Z

![]()

![]() Shift zero up by 50%: Alt+Shift+ Shift zero down by 50%: Alt+Shift+ Reset Zero Shift: Alt+Shift+Z

Shift zero up by 50%: Alt+Shift+ Shift zero down by 50%: Alt+Shift+ Reset Zero Shift: Alt+Shift+Z

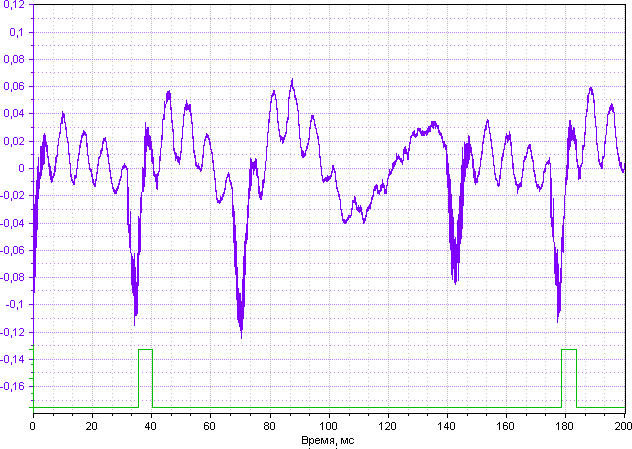

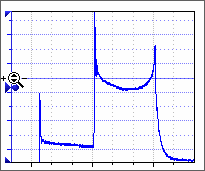

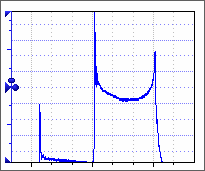

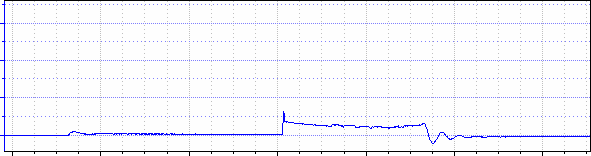

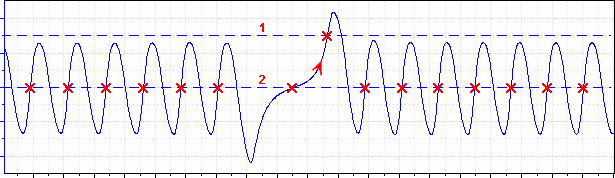

An example of using offset and zero shift:

|

| Offset and shift not Offset 80%, scale 150% Shift 1.4, scale 1000% are used |

![]()

![]()

![]() As you can see, the signal considered in the example is not symmetrical with respect to the base zero level, due to which the lower half of the axis height is not occupied by useful data, i.e. screen space is not being used effectively. If you perform a zero shift to the 80/20 position and increase the scale to 150%, then the considered signal will become symmetrical about the center of the axis, which is more convenient for analysis. If we perform a zero shift by an absolute value of 1.4 (only for the example under consideration) and zoom in to the maximum value, then it becomes possible to visually analyze the oscillations within the combustion region.

As you can see, the signal considered in the example is not symmetrical with respect to the base zero level, due to which the lower half of the axis height is not occupied by useful data, i.e. screen space is not being used effectively. If you perform a zero shift to the 80/20 position and increase the scale to 150%, then the considered signal will become symmetrical about the center of the axis, which is more convenient for analysis. If we perform a zero shift by an absolute value of 1.4 (only for the example under consideration) and zoom in to the maximum value, then it becomes possible to visually analyze the oscillations within the combustion region.

Note

When scaling with the mouse or a frame, an automatic zero shift is used to enable scaling without reference to the current zero value of the axis.

Charts and axes settings menu

In addition to the main parameters discussed above, each graph and the axis associated with it also have a number of additional parameters: the need to display the grid, labels, frames, blocks of parameters, line color and thickness, etc. To configure additional parameters of graphs and axes, the corresponding axis pop-up menu is provided, which is called by right-clicking on one of the axis markers or sliders (except for the offset / zero shift slider) or by right-clicking within the vertical axis scale area.

Keyboard shortcut:

Calling the active chart menu: Alt+M

Net (Alt+G)

Show/hide grid

Tags (Alt+T)

Show/hide axis labels

Frame (Alt+F)

Show/hide border

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

| Viewfinder (Alt+Shift+W) | Enable / disable the use of the reticle when zooming | |

| Icons (Alt+Shift+I) | Show permanently / auto-hide axis controls | |

| Name (Alt+Shift+N) | Show/hide axis title and graph | |

| Axis left (Alt+L) | Position Axis Along Left Screen Border | |

| Axis right (Alt+R) | Position Axis Along Right Screen Border | |

| Signal parameters (Alt+Shift+S) | Show / hide information about general signal parameters | |

| Marker Options

(Alt+Shift+M) |

Show/hide information about signal parameters under markers | |

| Stretch Axis (Alt+PgUp) | Stretch the selected axis and minimize other visible axes | |

| Line thickness | Submenu for selecting the thickness of the graph line | |

| Color | Open a window for choosing the color of the axis and graph | |

| Setting | Open axis and graph settings window |

Advice

It is advisable to use auto-hide of controls for screens with low resolution or when displaying a large number of charts at the same time.

Group setting of the same type of parameters

Most pop-up menu items support group setting of the same type of parameters, to apply which you need to click on the corresponding menu item while holding down the keyctrl. Group setting means simultaneous setting of one of the parameters of all visible charts based on the setting of the same parameter of the active chart. For example, in order to display labels for all visible charts at once, it is enough to call the pop-up menu for only one chart (active) and click on the “Labels” menu item while holding down the keyctrl, as a result, labels will be displayed for all visible graphs, i.e. the value of the “Labels” parameter of the active chart will be automatically copied to other visible charts.

| Advice

To determine if a menu item supports group setting, look at the corresponding tooltip for that menu item in the status bar. |

The “Settings” menu item also allows you to simultaneously adjust the scale, offset and zero shift of all visible vertical axes based on the values of the same parameters of the active vertical axis. For group settings of the listed parameters, it is necessary to click on the “Settings” menu item while holding down one or more modifier keys (the settings window does not open in this case):

§ for group scale adjustment it is necessary to hold down the keyalt, for group

§ adjustment of zero offset it is necessary to hold down the keyctrl, for group

§ adjustment of zero shift it is necessary to hold down the keyShift.

For example, while holding down only the key alt while clicking on the “Settings” menu item, the scale value of all visible vertical axes will be simultaneously set based on the scale value of the active vertical axis, and when you hold down the keys altand ctrl both the scale value and the zero offset will be set at the same time. Thus, depending on the key combination held simultaneously on the current axis, it is possible to adjust both one and several parameters at once. Group setting of the above axis parameters is convenient to use when analyzing several signals of the same type, for example, when analyzing secondary voltage, in raster or overlay display modes.

| Advice

When using the keyaltto prevent the pop-up menu from closing, you must first click the left mouse button on the “Settings” menu item, and then, without releasing the left mouse button, press the keyalt, then release the left mouse button. |

| Note

Group setting of the above axis parameters is not supported for all axes / channels, for example, the logical channel axis does not support and does not participate in group setting. |

Action groups with graphs / axes

An action group is a certain sequence of actions performed on the graphs visible on the screen in order to achieve one of the typical results. For example, various options for aligning graphs, i.e. setting the screen positions of each of the charts for their uniform placement within the working screen.

Keyboard shortcut for supported action groups:

Align the visible axes evenly from top to bottom along one side of the screen: Alt+Ctrl+1 Align the visible axes in pairs and evenly from top to bottom along both sides of the screen:Alt+Ctrl+2 Combine the centers of the visible axes:Alt+Ctrl+3 Set the initial positions of the axes:Alt+Ctrl+4

Parameter blocks

The parameter block is a container with a customizable size and location within the desktop, the main purpose of which is to display its context in the most convenient position for the user. The context refers to the specific information content of the block, for example, the context can be the general parameters of the signal, the name of the channel, or the scale of the ruler.

To move a blockyou need to move the mouse pointer into the inner space corresponding block, after the mouse pointer changes to a cross-shaped arrow, click the left mouse button within the borders of the block and drag it to the specified position. While moving the block, the status bar will display the coordinates of its upper left corner. To stop moving the block and fix the set location, release the left mouse button.

![]()

– move block

![]() To resize a block you need to move the mouse pointer to one of the borders or to one of the corners of the block, after the mouse pointer turns into a resizing arrow, click the left mouse button and drag the desired border or corner of the block to the specified position. While the block is being resized, the status bar will display its current size. To finish resizing the block and fix it, release the left mouse button.

To resize a block you need to move the mouse pointer to one of the borders or to one of the corners of the block, after the mouse pointer turns into a resizing arrow, click the left mouse button and drag the desired border or corner of the block to the specified position. While the block is being resized, the status bar will display its current size. To finish resizing the block and fix it, release the left mouse button.

![]()

![]()

![]()

![]()

![]()

![]()

Unit General Setting Menu

![]()

![]()

![]()

![]()

![]() In addition to customizable dimensions and location, each block has additional parameters: the need to fix the position and dimensions, the parameters for binding and gluing the block. To configure additional block parameters, a corresponding block pop-up menu is provided, which is called by right- clicking within the block boundaries.

In addition to customizable dimensions and location, each block has additional parameters: the need to fix the position and dimensions, the parameters for binding and gluing the block. To configure additional block parameters, a corresponding block pop-up menu is provided, which is called by right- clicking within the block boundaries.

| Lock position | ||

| Fix size | Deny / allow block resizing | |

| Hide block | Hide corresponding block | |

| Bind block | Block binding parameters: | |

| Automatically detect frame edge | ||

| Anchor block to the left edge of the frame | ||

| Anchor the block to the top edge of the frame | ||

| Anchor block to the right edge of the frame | ||

Stick block |

Anchor the block to the bottom edge of the frame

Block gluing parameters: |

|

| Stick block to screen borders | ||

Setting |

Glue the block to the borders of the frame

Open block settings window |

|

Note

The block setting menu also supports group settings of the same type of parameters.

Fixing the location and size of the block usually used only to prevent accidentally changing the previously set position and size of the block.

![]()

![]()

Block binding defines the edges of the desktop screen to which you want to maintain a distance from block when resizing the working screen, which allows you to visually save the location of the block relative to the corresponding edges of the working screen. For example, if the block is anchored to the left and top edges of the work screen, then when the work screen is resized, the distances to the left and top edges of the work screen will be preserved and the block will not visually change its position.

location relative to the top left corner of the home screen. If the block is anchored to the right and bottom edges of the work screen, then when the work screen is resized, the distances to the right and bottom edges of the work screen will be saved and the block will not visually change its location relative to the lower right corner of the work screen, but the location relative to the upper left corner of the work screen will change. Those. if the most convenient location of the block is near the upper left corner, then it is advisable to link the block to the left and upper edges of the working screen, and if the most convenient location of the block is near the lower right corner, then it is advisable to link the block to the right and lower edges of the working screen. When automatically determining the edges of the binding, the program itself determines the most convenient location of the block,

Block gluingis intended only for convenient positioning of blocks relative to home screen borders or home screen frame borders. When sticking is enabled, while moving a block near one of the borders of the working screen, the block will automatically stick to the corresponding border. When resizing the working screen, all glued blocks will automatically move after the border to which they are glued, i.e. visually, the block will not change its location relative to the corresponding border.

Block Axis Title and Plot

The block is designed to display the serial number and title of the graph.

The general setup menu is complemented by several parameters specific to this unit.

![]()

![]()

![]()

![]()

![]()

![]()

Number

Show / hide axis number

Name

Show/hide axis title text

Horizontally

Set horizontal text direction

Vertical

Set vertical text direction

Stick block

Block gluing parameters:

To linked axis

Glue a block to an associated axis

![]()

![]()

![]()

![]()

![]()

Stick block

Block gluing parameters:

To adjacent block

Glue a block to an adjacent block

To linked axis

Glue a block to an associated axis

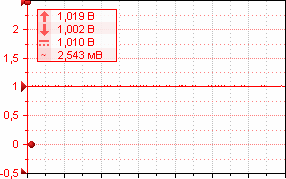

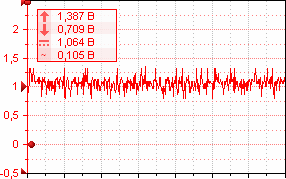

Signal parameter block

![]()

![]()

![]()

![]()

![]()

![]() The block is designed to display the general signal parameters of the corresponding chart. Under the general signal parameters are meant: the maximum and minimum values of the signal amplitudes, as well as the values of the constant and variable (rms) components of the signal. The general setup menu is complemented by several parameters specific to this unit.

The block is designed to display the general signal parameters of the corresponding chart. Under the general signal parameters are meant: the maximum and minimum values of the signal amplitudes, as well as the values of the constant and variable (rms) components of the signal. The general setup menu is complemented by several parameters specific to this unit.

| Show/hide minimum signal value | |

| Show / hide the value of the DC component of the signal | |

| Show / hide the value of the variable component of the signal |

![]()

![]()

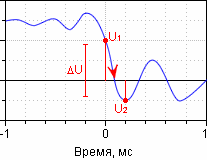

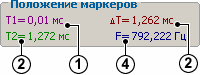

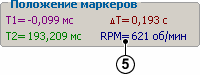

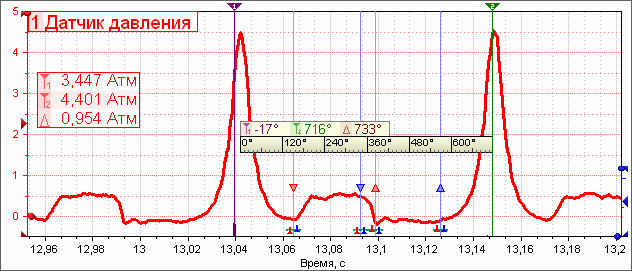

Marker parameter block

The block is designed to display signal amplitude values and their difference at the points indicated by vertical markers 1 and 2. The block provides a more detailed definition of signal amplitude values in comparison with visual estimation of the amplitude value on the scale of the corresponding axis.

![]()

![]()

![]()

![]()

![]()

![]() The general setup menu is complemented by several parameters specific to this unit.

The general setup menu is complemented by several parameters specific to this unit.

| Show / hide signal amplitude value under marker 1 | |

| Show / hide signal amplitude value under marker 2 | |

| Show / hide signal amplitude difference under markers | |

| Block gluing parameters: |

![]()

![]()

![]() Gluing a block to an adjacent blockdesigned for easy positioning only relative to each other the block of signal parameters and the block of parameters of markers belonging to the same axis.

Gluing a block to an adjacent blockdesigned for easy positioning only relative to each other the block of signal parameters and the block of parameters of markers belonging to the same axis.

![]()

![]()

To adjacent block

Glue a block to an adjacent block

To linked axis

Glue a block to an associated axis

Gluing a block to an associated axis provides automatic movement of the block following by moving the axis to which the block belongs.

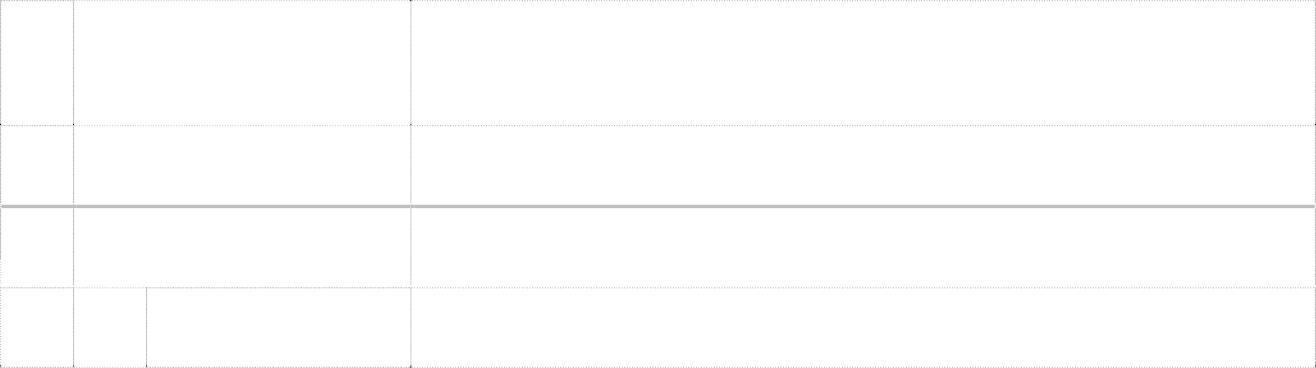

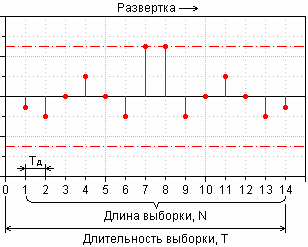

Horizontal axis

The following elements are used to effectively control the horizontal axis:

![]()

- Zoom out button (signal/axis shrink).

- Button for accessing the list of scales, displaying the currently set scale.

- Zoom button (signal/axis stretch).

- Scroll bar for navigation along the horizontal axis.

Frame controls (only available in frame-by-frame horizontal axis mode). 5. Button to go to the first frame.

- Button for moving to the previous frame.

- Panel displaying the number of the current frame and the total number of recorded frames.

- Button for moving to the next frame.

- Button to go to the last frame.

A. Button to start/stop the automatic playback of the frame sequence.

Change the scale of the horizontal axis

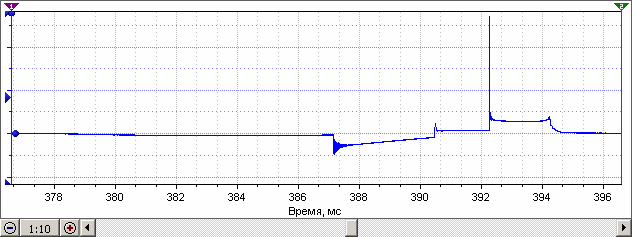

The software allows both zooming in and out of the horizontal axis (only in recorder mode). Zooming in (stretching the signal / axis) is convenient to use when you need a detailed analysis of short sections of the signal. Zooming out (signal / axis compression) allows you to display long signal intervals in a compressed form, which is advisable to use if you need to analyze the evolution of a signal over time.

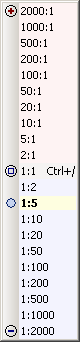

Horizontal axis scaling uses a discrete list of scales that are multiples of 2, 5, and 10. A scale of 1:1 means no squeezing or stretching. When zoomed out, the scales take values from 1:2 (compression by 2 times) to 1:2000 (compression by 2000 times); ).

Horizontal axis scaling uses a discrete list of scales that are multiples of 2, 5, and 10. A scale of 1:1 means no squeezing or stretching. When zoomed out, the scales take values from 1:2 (compression by 2 times) to 1:2000 (compression by 2000 times); ).

To zoom in or outper discrete value from the list scale, click on the zoom in or zoom out button, respectively.

To select one of the available scales from the listyou need to click on button to access the list of scales, and then in the list that appears, select the required scale with a mouse click.

In the scale list, the zoom values are displayed on a light red background and go up from the 1:1 value, and the zoom out values are displayed on a light blue background and go down from the 1:1 value.

The currently selected scale is shown in bold on a light yellow background with a selection pointer opposite its value.

Keyboard Shortcuts:

Zoom in:Ctrl+’+’ Zoom out:

Ctrl+’-‘

Set initial scale 1:1:Ctrl+’/’

The scaling methods described above perform scaling only relative to the center of the horizontal axis, which is not very convenient, for example, if you need to increase the portion of the signal that is currently not in the center of the horizontal axis. For scaling without reference to the center of the horizontal axis, scaling is provided relative to the current position of the mouse pointer, which is temporarily taken as the “center” of scaling.

Forchange the scale of the horizontal axis with the mouseit is necessary to bring the mouse pointer to the center of the analyzed section of the signal and press the keyctrl,after the mouse pointer changes to a magnifying glass, left click to zoom in, right click to zoom out, middle click to zoom in 1:1. With each click, the scale will change according to the list of discrete scale values, except in the case of setting the scale to 1:1, which will be set immediately after the first click.

![]()

– scaling start (‘+’ – increase with the left button, ‘-‘ – decrease with the right button)

To reduce the number of clicks when it is necessary to change the scale by several discrete values at once and maintain the possibility of scaling without reference to the center of the horizontal axis, scaling is provided using the scaling box.

Forscaling with frameit is necessary to bring the mouse pointer to the beginning of the analyzed section of the signal and press the key ctrl, after the mouse pointer takes the form of a magnifying glass, click the left mouse button to zoom in or the right mouse button to zoom out, and then, without releasing the mouse button, select the required signal section using the semi-transparent frame that appears. To complete the zoom, release the mouse button, and to interrupt the zoom, press the key Escuntil the mouse button is released. When increasing, the selected area will be increased by the entire width of the axis, when decreasing, the selected area sets the required width of the axis.

When zooming with a frame, the mouse pointer changes to the following:

![]()

![]()

– with an increase – when decreasing

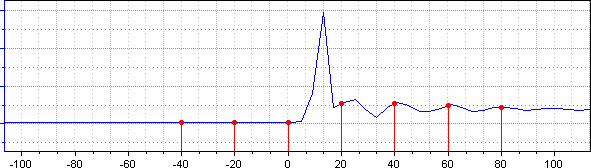

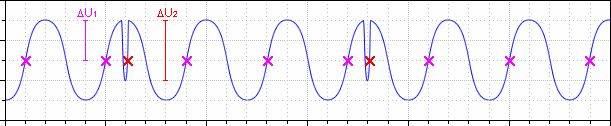

An example of changing the scale of the horizontal axis using the zoom box:

original scale

Dedicated area

Scale result

As you can see when zooming in using the zoom box, the required signal section is located in the center of the axis – in the most convenient place for its further visual analysis.

Navigation along the horizontal axis

To navigate along the horizontal axis, it is mainly used scroll bar. It is possible to move the analyzed signal along the horizontal axis either by moving the slider or by clicking on the corresponding buttons on the scroll bar. In addition, it is possible to use the mouse wheel to move, and if you hold down the key while scrollingctrl then scrolling will be accelerated five times.

The width of the slider is proportional to the ratio of the length of the signal section displayed on the screen to the total length of the signal, i.e. the longer the signal or the smaller the section of the displayed signal, the narrower the slider. By the width of the slider, it is possible to quickly estimate the length of the displayed section of the signal to the total length of the signal.

Keyboard Shortcuts:

![]()

![]() Move Left 10%: Move Right 10%: Move Left 100%:pgup Move right 100%:

Move Left 10%: Move Right 10%: Move Left 100%:pgup Move right 100%:

pgdown Jump to the beginning of the post:Ctrl+PgUp Skip to the end of the entry:Ctrl+PgDown

Scrolling the horizontal axis is also possibleusing the mouse, to do this, move the mouse pointer to the area between the horizontal axis and the bottom border of the screen, after the mouse pointer takes the form of the beginning of scrolling, click the left mouse button and, without releasing it, move the mouse pointer along the horizontal axis, which will move after the mouse pointer. If you use the right mouse button instead of the left mouse button when scrolling the axis, the scrolling will be five times faster.

![]()

![]()

– start of axis scrolling

– axis scroll

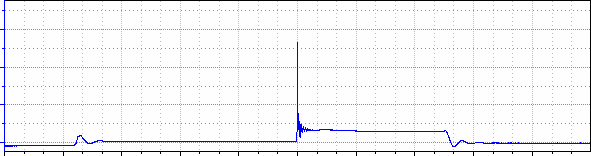

Viewing the signal while recording

During the recording process (recorder mode, history graphs), data accumulation is performed continuously in real time, while the screen usually displays not the entire recorded signal, but only its end (the length of the signal section displayed on the screen is determined by the current scale), i.e. waveform graphs shift from right to left, simulating the movement of the recorder tape. If it is necessary to view the recorded data directly during the registration process, it is enough to simply go to the analyzed section of the signal, using, for example, the scroll bar. The software will immediately suspend the automatic transition to the end of the recording, but at the same time continue further continuous accumulation of data, i.e. data logging will not stop. While viewing while recording, all horizontal axis controls are also available, ie. it is possible to perform zooming, navigation along the axis, etc. To resume the automatic transition to the end of the recording, you must

![]()

Translated from Russian to English – www.onlinedoctranslator.com

![]()

Interface elements

manually jump to the end of the recording, using, for example, the scroll bar or the corresponding keyboard shortcut.

Advice

To quickly jump to the end of a recording, use the keyboard shortcut: Ctrl+PgDown

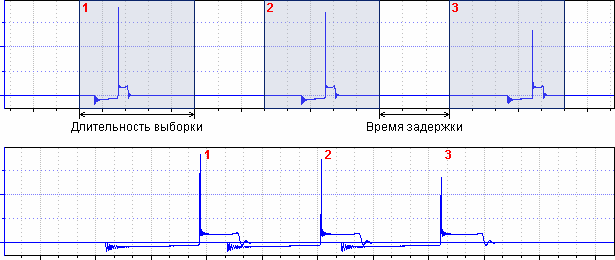

Personnel control panel

A frame is any abstract contiguous array of data, such as one oscilloscope sample, one complete engine cycle in the secondary ignition analysis window, etc.

Navigating through the available frames is basically done by clicking on the corresponding button on the frame bar. Fordirect setting of the frame number it is necessary to double-click on the panel displaying the number of the current frame and the total number of recorded frames, after which an input field for the direct building of the frame number will appear in place of the panel. The number of the current frame will change directly during the input process. To close the input field, press the keyEnter or double click on the input field.

![]()

![]()

Change frame by clicking on a button

Immediate frame number building

Keyboard Shortcuts:

Go to first frame: ctrl+home Go to previous frame: Home Go to next frame:

end Go to last frame: ctrl+end

In the frame accumulation process is also supported frame view mode. To pause the automatic transition to the last recorded frame, you must go to the analyzed frame, and to resume the automatic transition to manual, go to the last frame.

Note

To use a keyboard shortcut, the input focus must be on the scroll bar, frame control bar, or the corresponding work screen.

Advice

To quickly transfer input focus to the currently visible home screen, pressCtrl+Enter.

Selected area

The program allows you to select an arbitrary section of the signal, to ensure its subsequent saving, export, or, if necessary, further processing.

The figure shows the following elements:

The figure shows the following elements:

-

-

- Marker for moving the left border of the selected area

- Selected area

- Selected section of the signal

- Marker for moving the right border of the selected area

-

To select a signal section, move the mouse pointer to the beginning of the desired section, click the left mouse button, and then, without releasing the left mouse button, select the required signal section using the semi-transparent frame that appears. To complete the selection, release the left mouse button. To remove the selection, just click the left mouse button within the working screen.

Markers for moving the boundaries of the selected area(1) and (4) are designed to correct the boundaries of the current selected area. It is advisable to use markers if it is necessary to perform a small modification of the selected area, and a new selection of a signal section is less effective, for example, due to the additional need to correct the scale or move the axis.

To move one of the borders of the selected area, move the mouse pointer to the corresponding marker, after the mouse pointer takes the form of an index finger, left-click on the marker and drag it to the desired position, the corresponding border of the selected area will move after the marker. To stop moving the border of the selected area and fix it, release the left mouse button.

![]()

– moving the boundaries of the selected area

Keyboard Shortcuts:

Select the entire signal: Ctrl+A

Select the signal visible on the screen: Ctrl+Shift+A

![]()

![]() Remove selection from the selected section of the signal: Ctrl+Shift+D Move the left border of the selection to the left / right: Shift+ Move the right border of the selected area to the left / right: ctrl+

Remove selection from the selected section of the signal: Ctrl+Shift+D Move the left border of the selection to the left / right: Shift+ Move the right border of the selected area to the left / right: ctrl+

![]() , Shift+

, Shift+

![]() , Ctrl+

, Ctrl+

Note

It is possible to select a section of a signal only in the presence of a signal.

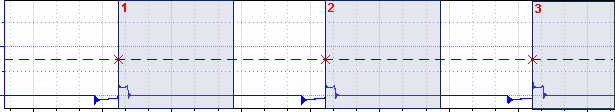

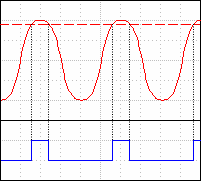

Vertical and horizontal markers

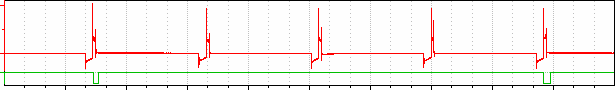

Credibility markers are designed to provide a detailed view of the main signal parameters displayed in signal parameter blocks, measure intervals on the horizontal axis and designate different parts of the signal. Horizontal markers are designed to set the level values used for absolute synchronization, threshold values for comparing the input signal amplitude for a logical channel, etc.

To move the marker, move the mouse pointer to the marker pointer, usually in the form of a triangle, after the mouse pointer takes the form of an index finger with arrows indicating the direction of movement, left- click on the marker pointer and drag it to the desired position. Usually, while moving a verification marker, its position will be displayed on the “Position of markers” panel, and while moving a horizontal marker, the corresponding threshold or level value will be displayed in the status bar, as well as a hint label on the opposite side to the marker pointer. To complete the movement of the marker and fix its position, release the left mouse button.

![]()

![]()

– move credential marker

– move horizontal marker

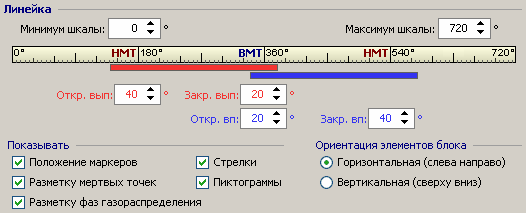

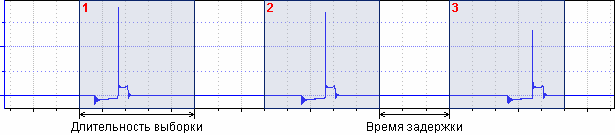

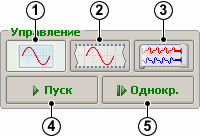

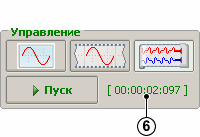

Advice